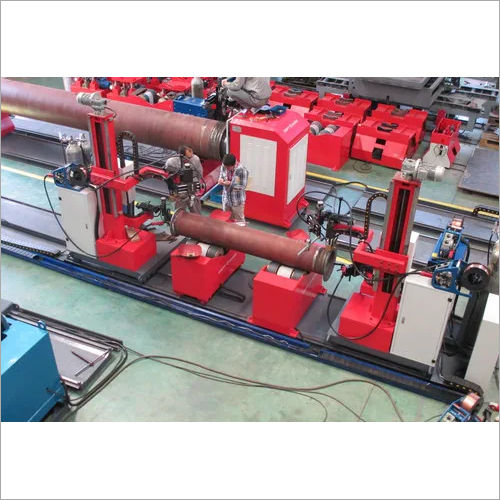

Pipe Welding Machine

25000.00 - 40000.00 USD ($)/Set

Product Details:

- Weight 234 Kilograms (kg)

- Color Gray or as per request

- Product Type Pipe Welder

- Condition New

- Material Stainless Steel

- Voltage 380 - 220 Volt (v)

- Dimensions 1800*1200*2300 Centimeter (cm)

- Click to view more

X

Pipe Welding Machine Price And Quantity

- 25000.00 - 40000.00 USD ($)/Set

- 1 Set

Pipe Welding Machine Product Specifications

- 1800*1200*2300 Centimeter (cm)

- 234 Kilograms (kg)

- 380 - 220 Volt (v)

- Gray or as per request

- Pipe Welder

- New

- Stainless Steel

Pipe Welding Machine Trade Information

- 20 Set Per Month

- 45 Days

Product Description

Introducing our advanced pipe welding machine, the ultimate solution for achieving impeccable welds with unparalleled precision and efficiency. Designed with cutting-edge features and top-notch performance, this machine is poised to revolutionize the welding industry and meet the highest standards of quality.

The pipe welder machine boasts exceptional versatility, accommodating various pipe sizes and materials. Whether you're working with stainless steel, carbon steel, or other alloys, this machine adapts effortlessly to your specific welding needs. Its adjustable settings and advanced technology ensure consistent and flawless welds every time.

Powered by state-of-the-art automation capabilities, our machine streamlines the welding process, delivering exceptional precision and efficiency. With precise control over critical parameters such as voltage, current, and wire feed speed, operators can achieve optimal results without any guesswork. Bid farewell to manual errors and welcome superior weld quality.

Safety is paramount, and the Pipe Welder Machine prioritizes operator well-being. Equipped with comprehensive safety features, including protective shields, emergency stop buttons, and automatic shutdown mechanisms, it ensures a secure working environment. Rest assured that your team is protected during welding operations, reducing the risk of accidents and injuries.

What sets our Pipe Welding Machine apart is its exceptional efficiency. By automating time-consuming tasks and optimizing welding parameters, it significantly reduces production time, leading to improved productivity. With its high welding speed and consistent results, you can meet demanding deadlines without compromising on quality, driving your business towards success.

Investing in our Pipe Welder is a strategic move towards elevating your welding operations. With its cutting-edge technology and precise performance, you gain a competitive edge in the market and deliver superior welds that exceed expectations. Its exceptional reliability and efficiency empower you to take on complex projects and establish a reputation for excellence.

Don't settle for subpar welding machines. Upgrade to our Pipe Welder today and experience the transformative impact it has on your welding projects. Contact us now to learn more about this innovative machine and how it can revolutionize your welding operations for the better.

Pipe Welding Machine Features:

1. On-line Performance: Good (Designed as per the one line equipment of the production line)

2. Welding Efficiency: Excellent (100~150 inch/day, which is 4 times higher than the manual welding)

3. Operability: Very good (applicable and easy to operate even if you are a new user within a short period of time)

4. Surface finishing: Good (the welding gun will always be positioned in the optimum position)

5. Welding compliance rate: 98% min (without re-working for the skilled operator).

6. Driving Reliability: Good (driven with friction; the necessary balance weight shall be provided for the pipe with DN600 and which the wall thickness is 40 to balance the serious eccentricity resulted from bending).

Pipe Welding Machine Specifications:

1. Current: 70-800A

2. Rated Capacity: 30KW

3. Rated Duty Cycle: 120%

7. Certification: ISO,CE

8. Core Components: PLC, Engine, Motor

9. Video outgoing-inspection: Provided

10. Machinery Test Report: Provided

11. Warranty of core components: 1 Year

12. Warranty: 1 Year

13. Pipe diameter applicable: DN400~800(426~810)

14. Pipe wall thickness applicable: 18~80MM

15. Materials applicable: carbon steel, alloy steel, stainless steel and cryogenic stee

16. Welding line applicable: Various welding lines of tube sections such as tube tube, tube elbow, tube flange, flange flange and flange elbow, etc (a fake pipe transition connection shall be applied if necessary).

17. Driving system: Two rows of metal + rubber compound idler wheel driven by motor.

18. Clamping system: Clamping with double chain clamping mechanism

19. Bracket System: Separate type of trolley matching for welding machine, which may be adjusted along the track according to the length of the pipeline.

20. Speed regulation Mode: VF stepless speed control system

21. Control system: A product of our patented technology.

22. Welding mode: Thick and single double wire SAW.

23. Welding Power: Our OEM products which are famous in China (or as per customers demands)

Pipe Welding Machine FAQ:

Q. What is a pipe welding machine?

Ans: A pipe welder is a specialized welding equipment designed for joining pipes together through welding processes. It provides the necessary power and control to perform efficient and quality welds on pipes.

Q. What types of welding processes are used with pipe welding machines?

Ans: Common welding processes for pipe welding include Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW).

Q. What are the main components of a pipe welder?

Ans: The main components typically include a power source, welding cables, a welding gun or torch, a wire feeder (for some processes), and a control panel for adjusting welding parameters.

Q. What types of pipes can be welded with a pipe welding machine?

Ans: Pipe welders are versatile and can be used to weld various types of pipes, including carbon steel, stainless steel, aluminum, and other alloys. The machine's capabilities often depend on the welding process and the specific machine model.

Q. How do I choose the right pipe welding machine for my application?

Ans: Consider factors such as the type of welding process needed, the material of the pipes, the thickness of the pipes, and the specific welding requirements. Additionally, evaluate the machine's power output, duty cycle, and portability based on your project needs.

Q. What is the duty cycle of a pipe welders?

Ans: Duty cycle refers to the percentage of time a welding machine can operate within a 10-minute period without overheating. It's crucial to choose a machine with a duty cycle that matches your welding needs. Higher-duty-cycle machines are suitable for continuous or heavy-duty welding applications.

Q. Can pipe welding machines be used for both on-site and workshop applications?

Ans: Yes, many pipe welders are designed to be portable, allowing them to be used for on-site welding as well as in workshop settings. Consider factors like weight, size, and power source compatibility when choosing a machine for specific applications.

Q. How do I maintain a pipe welder?

Ans: Regular maintenance includes cleaning components, checking for loose connections, inspecting cables, and ensuring proper ventilation for cooling. Follow the manufacturer's guidelines for maintenance, and schedule periodic inspections to keep the machine in optimal working condition.

Q. What safety precautions should be taken when using a pipe welding machine?

Ans: Wear appropriate personal protective equipment (PPE) such as welding helmets, gloves, and flame-resistant clothing. Ensure proper ventilation, follow safety guidelines, and be aware of potential hazards associated with welding, such as fumes and arc radiation.

Q. Can a pipe welding machine be used for automated welding processes?

Ans: Yes, some pipe welders are compatible with automated or robotic welding systems, allowing for increased efficiency and precision in large-scale production environments. Automated welding systems often use specialized equipment for seamless integration with pipe welding machines.

Enter Buying Requirement Details

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free