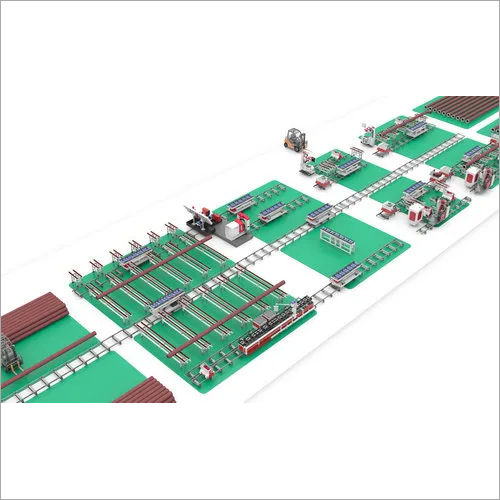

Pipe Fabrication Production Line (Fixed Type)

4999.00 - 9999.00 USD ($)/Set

Product Details:

- Power Source Electricity

- Operating Type Automatic

- Usage & Applications Industrial

- Click to view more

X

Pipe Fabrication Production Line (Fixed Type) Price And Quantity

- 4999.00 - 9999.00 USD ($)/Set

- 1 Set

Pipe Fabrication Production Line (Fixed Type) Product Specifications

- Automatic

- Industrial

- Electricity

Pipe Fabrication Production Line (Fixed Type) Trade Information

- 10 Days

Product Description

A Pipe Fabrication Production Line (Fixed Type) is a manufacturing process specifically designed for the efficient and cost-effective production of pipes. This process typically involves several stages, each contributing to the creation of high-quality pipes that meet industry standards.

Here's a basic outline of how a pipe fabrication production line might operate:

1. Material Selection: The process begins with selecting the appropriate materials for the pipes. This could include various types of metals (such as steel, stainless steel, or copper) or plastics (such as PVC or HDPE), depending on the intended use of the pipes.

2. Cutting and Shaping: Once the materials are selected, they are cut into the desired lengths and shapes. This may involve using cutting machines, saws, or other equipment to precisely shape the material according to the specifications of the pipes being produced.

3. Forming and Welding: The shaped materials are then formed into the cylindrical shape of pipes using bending machines or other forming equipment. In the case of metal pipes, welding processes such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding may be used to join the edges of the material together to create seamless pipes.

4. Finishing and Surface Treatment: After the pipes are formed and welded, they may undergo additional processes to improve their surface finish and corrosion resistance. This could include processes such as sandblasting, polishing, or applying protective coatings.

5. Quality Control: Throughout the production process, quality control measures are implemented to ensure that the pipes meet the required specifications and standards. This may involve visual inspections, dimensional measurements, pressure testing, or other quality assurance techniques.

6. Packaging and Shipping: Once the pipes have passed quality control checks, they are packaged according to customer requirements and prepared for shipping to their final destination.

Enter Buying Requirement Details

Send Inquiry

Send Inquiry