High Pressure Water Jet Cutting and Beveling Machine

20000.00 - 50000.00 USD ($)/Set

Product Details:

- Drive Motor AC Servo Motor

- Product Type Automatic Water Jet Cutting Equipment

- General Use Precise Industrial Cutting & Beveling

- Material Stainless Steel / Mild Steel / Glass / Ceramic / Stone / Composite

- Type High Pressure Water Jet Cutting and Beveling Machine

- Capacity Industrial Grade Continuous Operation

- Weight (kg) Approx. 3500 Kg

- Click to View more

X

High Pressure Water Jet Cutting and Beveling Machine Price And Quantity

- 20000.00 - 50000.00 USD ($)/Set

- 1 Set

High Pressure Water Jet Cutting and Beveling Machine Product Specifications

- 1500 mm x 3000 mm

- Servo Motor Driven

- High Pressure Water Jet Cutting and Beveling Machine

- 4000 mm x 2200 mm x 1800 mm

- Up to 6000 mm/min (material dependent)

- Yes

- Industrial Grade Continuous Operation

- CNC Controller with Waterjet Cutting Software

- Precise Industrial Cutting & Beveling

- Abrasive or Pure Water Jet Cutting

- Industrial CNC Control Panel

- High Pressure Jet, Precise Beveling, Versatile Cutting

- 0.05 mm

- Up to 200 mm (material dependent)

- AC Servo Motor

- 380V / 50Hz / 3 Phase

- Fully Automatic

- Water Cooling System

- 30 kW High Pressure Pump Motor

- Stainless Steel / Mild Steel / Glass / Ceramic / Stone / Composite

- Cutting and Beveling

- Metals, Glass, Stone, Composites, Rubber, Ceramics

- Automatic Water Jet Cutting Equipment

- Standard Industrial Grey

- Approx. 3500 Kg

High Pressure Water Jet Cutting and Beveling Machine Trade Information

- 20 Set Per Month

- 45 Days

Product Description

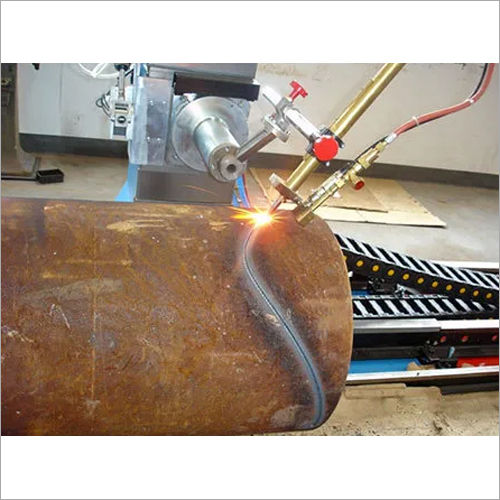

Facilitated by our technically advanced process, we are manufacturing, exporting and supplying a precision engineered collection of High Pressure Water Jet Cutting and Beveling Machine. It is widely used to cut pipes with heavy wall thicknesses in steel, construction and engineering industries. We manufacture the offered machine using high-grade components and leading-edge technology. Also, we test this machine upon a series of tests ensuring its overall performance. Our prestigious clients can avail the offered machineat industry leading price.

High-Pressure Water Jet Cutting and Beveling Machine is an engineering technique that uses the energy of high-speed, high-density, ultra-high-pressure water to cut objects. A water jet with devastating force is created when water is compressed by an ultrahigh-pressure pump to a speed of nearly three times the speed of sound.

High-Pressure Water Jet Cutting and Beveling Machine Features:

- Water jet cutting is a non-contact method of processing.

- There is no limit to the number of things that can be targeted

- There are no drills or other tools in contact with the object, thus no heat is generated.

- There is no dust produced, thus workers and the environment are unaffected.

- High-Pressure Water Jet Cutting and Beveling Machine has a low power consumption

- Furthermore, processing can be done using only water and sand, making it eco-friendly.

- Stone, marble, ceramics, porcelain, and tile may all be cut with an abrasive cutting machine.

Applications:

- Waterjet cutting is great for putting inlays and logos in stone and tile applications because it maximizes performance, lowers costs, and increases profit. High-Pressure Water Jet Cutting and Beveling Machine have a wide range of applications, including cutting roof materials, dashboards, and bumpers for automobiles, to name a few. Its also utilized for cutting new-material aircraft fuselages.

Specifications:

- Pipe Diameter Applicable

- Applicable Wall Thickness: 550 mm

- SH-2000H Flame CNC Cutting System is used as a control system

- Length Fixing Accuracy:<2.0MM

- 6350MM trolley travel is required

- Bevel Shape: V

- Cutting Direction: Lengthwise

Precision Beveling for Versatile Applications

With a bevel angle range of 0 to 60, this machine enables precise edge preparation for welding, fabrication, or architectural requirements. The servo-driven system and 0.05 mm mechanical precision guarantee consistent results on materials like stainless steel, ceramics, composites, and stone. Beveling and cutting can be automated via CNC software for improved repeatability and reduced manual intervention. The systems versatility makes it ideal for factory, workshop, and high-volume export operations.

Advanced Operator Control with Touch Screen HMI

The integrated touch screen HMI and industrial CNC controller simplify operation, allowing users to manage cutting parameters, abrasive flow, and bevel angles efficiently. Automated safety features, such as emergency stop and overload protection, ensure secure handling during industrial processes, while installation support is available on request for seamless setup.

FAQs of High Pressure Water Jet Cutting and Beveling Machine:

Q: How does the High Pressure Water Jet Cutting and Beveling Machine achieve precise bevel angles?

A: The machine utilizes a computerized CNC controller and servo motor-driven head to accurately position the nozzle, ensuring precise bevel angles from 0 to 60. Operators can select the required angle through the touch screen HMI, and the system automatically adjusts the head for consistent, high-quality edge preparation.Q: What materials are suitable for cutting and beveling with this machine?

A: This machine is designed for high-pressure abrasive or pure water jet cutting, making it compatible with stainless steel, mild steel, glass, ceramics, stone, composites, rubber, and other industrial materials. The recommended abrasive is Garnet 80 Mesh for optimal cutting performance.Q: When is abrasive jet cutting recommended over pure water jet cutting?

A: Abrasive jet cutting is recommended for tough materials such as metals, stone, and ceramics that require penetration strength and clean edges. Pure water jet cutting is suitable for softer materials like rubber or certain composites, where abrasives are not required.Q: Where can installation and support services for this machine be requested?

A: Installation services are available on request through the distributor, exporter, manufacturer, supplier, or trader. Support can be arranged during purchase from qualified dealers in China, ensuring proper setup for industrial environments.Q: What are the operational safety features integrated into the machine?

A: The system is equipped with an emergency stop, overload protection, and centralized automatic lubrication. These features ensure operational safety, protect components, and reduce the risk of accidents during continuous industrial usage.Q: How does the automatic abrasive delivery system benefit the cutting process?

A: The adjustable flow abrasive delivery system ensures optimal abrasive quantities are met based on material and cutting parameters. This not only enhances cutting performance and precision, but also extends the nozzles service life and reduces wastage.Q: What are the main advantages of using this high-pressure water jet cutting machine?

A: Key benefits include precise, versatile cutting and beveling up to 200 mm, computerized control for repeatability, low noise (<80 dB), minimal thermal distortion, and compatibility with a wide range of industrial materials. Its continuous operation capacity and advanced safety features support demanding production environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry  Call Me Free

Call Me Free